Editor’s update (12/16/2014): This post, and the technology discussed, have generated some great discussion! Head to the bottom of Steve’s original post for thoughts from former EPA employee Krista Durlas, and a response from BioHiTech CEO Frank Celli.

—-

The United Nations Environment Program says about one third of the food produced in the world for human consumption is either lost or wasted. That means millions of tons of food waste have to be disposed of each year. Tossing it into landfills creates methane, which is 20 times more damaging to the atmosphere than carbon dioxide, according to the EPA.

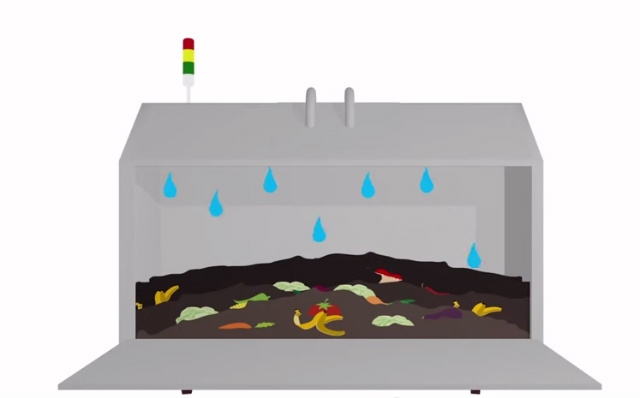

BioHitech, a New York-based company, has developed the EcoSafe Digester, an aerobic unit that breaks food waste down into grey water so it can be safely flushed down the drain. The company says its digester is like a “mechanical stomach,” in which an ideal combination of heat, moisture and oxygen enables microorganisms to thrive and break down the food scraps it is fed. The largest EcoSafe Digester uses up to 300 gallons of fresh water and discharges 400 to 500 gallons of effluent in a 24 hour period.

The machine is designed to operate on-site, where it can help reduce the amount of food waste that ends up in a landfill. And it is connected wirelessly to BioHiTech’s computer cloud, providing the company’s technicians with information about digestion rates, utility usage, hours of operation, maintenance issues and other features of the digester’s work. If problems arise, such as interruption of digestion or any other anomalies, a real time notification system allows BioHitech to respond quickly.

The company is able to remotely control each unit through its cloud and make performance adjustments from anywhere in the world at any time. The system can identify trends and inefficiencies that lead to waste, allowing customers to understand the historical patterns of food waste and take steps to avoid it in the first place.

If necessary, computerized records are available to help customers substantiate that they are in compliance with waste disposal regulations. And as an extra bonus, BioHiTech will help publicize that a customer is using an EcoSafe Digester to promote its green credentials in the community.

All in all, the EcoSafe Digester is good for the the company, good for customers and good for the environment.

via gizmag

Featured image credit: Screen capture from “The BioHitech America Food Waste Solution” video

Editor’s update #1: I suggested this story to Steve; when I read the gizmag post, “food waste,” “grey water,” and “big data” all caught my eye. What I should have thought about just a bit more was the notion of sending this material into the sewage system. Krista Durlas, who teaches sustainability issues at Webster University, and has worked for the EPA, and Whole Food’s sustainability team (and who’s also a friend), offered some insight on this technology at Facebook:

Normally love sustainablog posts, but these are a bad idea and this product name and using the term “grey water” is misleading. This technology concentrates nutrients into waste water which otherwise wouldn’t be there at all. It’s basically like dumping fertilizer into rivers. Excess nutrients in waste water causes eutrophication (dead zones in water bodies) If they could siphon off all the nutrients into some kind of fertilizer that would be great. But flushing it down the drain is a shell game. The real point is that where there is food waste, the nutrients from that biomass need to be returned to the soil where food is grown. I have seen these in action and have tried to discuss with their sales staff. They either don’t understand or don’t want to.

Krista offered to let me soften some of the rough edges of her comments, but I think she’s identified some genuine concerns here – those shouldn’t be softened! Of course, anyone who’d like to respond to her thoughts is welcome… but I think she’s probably right on target (and I’m smacking myself in the head just a bit…)

Editor’s update #2: BioHiTech’s CEO asked to respond to Krista’s thoughts; that struck me as perfectly reasonable. So here – unedited – is his “letter to the editor”:

To Mr. McIntire-Strasburg

As a 25 year waste industry veteran I am sure of two things. There is no one solution to the world’s problem of food waste disposal and without transparency and accurate insight to waste generation it is nearly impossible for the generators to create efficiencies to reduce what is generated. We have to agree that this is the paramount issue. How we dispose of it is secondary. Our technology allows for the collection and provision of this data in real time with no guesses!

That being said, we have to realize that no one solution can solve this massive problem. The likely solution is a combination of various technologies depending on an area or customer’s specific requirements.

I don’t disagree with eutrophication, it is a fact. However, digesters such as ours (that work correctly) have insignificant levels of nutrients remaining in the discharge AND the total discharge from our units is non-material in the total discharge from our customers to WWTPS. Also, this discharge is not just sent to water bodies, it is first treated at waste water treatment plants with all of the rest of the waste water generated from hospitals, hotels, supermarkets, etc. The clean water is then discharged safely to waterways while the residual sludge is disposed of accordingly. Many of these facilities actually do send the sludge to compost facilities or even better to anaerobic digesters that then convert this waste product into useful gas for power generation. So ultimately, the nutrients are in fact being utilized for beneficial purposes.

Doesn’t it make sense to eliminate all of the excess truck traffic and heavy equipment processing needed to transport and process raw food waste into compost material? Collection trucks used for this transportation only get 4-5 miles per gallon and emit both carbon monoxide and dioxide. Never mind the equipment and energy needed at the compost facility. That is an enormous amount of emissions and I would venture to say largely negate the benefit of composting all together.

I am not opposed to composting, it along with AD, on site equipment like ours and others are all key components in creating the most sustainable environment we can. The problem is that many compost and AD facilities are long distances from metropolitan areas and require huge amounts of logistics to reach and are costly and not environmentally sound. On top of that, does anyone ever think about where all this compost will go? Is there a need? How much additional energy and fuel is needed to package and transport it to a location where it can ultimately be distributed?

Again, I believe and support all of these options but we have to assess each opportunity independently. In areas where compost facilities are readily accessible, compost. Where AD is accessible then utilize it. In areas where neither are a viable options utilize an on site technology.

At BioHitech America, we are realistic about the fact that all of these alternatives should be part of the big picture but lets find a way to utilize them all in the most environmentally friendly way while providing our customers with what they need to eliminate the problem all together. We are working with an AD company right now to tank our effluent and decant the clean water component leaving only what remaining nutrients are left. By doing this we can reduce the amount of material that needs to be transported by 80% or more providing a more viable feedstock to AD without the economic burden to the consumer. That is the type of innovation we support. Working together and embracing all technologies to find the optimal solution is the ultimate approach!

In each and any case, providing accurate, usable data is the key to ultimate sustainability. I welcome the opportunity to talk with or meet Ms. Durlas any time as her opinion is valid. I would hope she can open her mind to the fact that there is no sole solution and everything should be considered in order to protect our environment.

Frank E. Celli

Chief Executive Officer

Update #3: Krista responds… it’s in the comments.

Steve Hanley

Having written this story at Jeff’s request, I want to say that I can see Ms. Durlas’ and Mr. Celli’s point of view. And I want to commend Mr. Celli for his measured response.

Without assessing the merits of either position, I will say that an exchange of ideas coupled with giving opposing points of view a respectful hearing USED to be considered hallmarks of a civil society. Sadly, in today’s environment where corporations spend billions on spin doctors whose only concern is to stay “on message”, (and cash their lucrative paychecks), the ability to hold productive debates on topics that are of vital interest to us all and to our planet is almost non-existent.

One of the objectives of this website is to promote such reasoned discourse. We need more of this and we need to recognize that all stakeholders are entitled to have input into the deliberative process.

Krista Durlas

I appreciate the thoughtful response and agree there are no perfect solutions. I also acknowledge that we’re both working toward the same goal.

I’m an academic now and have no stake in whether people buy your product or not. When I worked in the food industry, I originally learned about your product in a series of sales pitches.

I’m honestly not trying to be argumentative. The issue remains that without seeing actual numbers for the nutrient loading, I don’t find the “Trust us, it’s safe.” argument compelling. As I mentioned in my original response, if you won’t be transparent about discharge levels, then I have to assume it’s because there’s a good reason.

If the food waste practically disappears and the digester discharges pure water, then where do the nutrients in tons of food waste go? Anaerobic digestion of organic waste typically yields high concentrations of nutrients in the resulting waste water. If your machine can do otherwise, you could get very rich selling it to

farmers.

Obviously, nothing from your equipment is discharged directly into a receiving water body. However, waste water treatment plants are not typically designed to

remove total nitrogen or total phosphorus to levels that are safe for the environment. Therefore, the discharge from your machines is just passing

through.

It takes a lot of money, chemistry and energy to strip nutrients back out of water. Because of the problem of eutrophication, there is mounting pressure to force treatment plants to start treating for nutrients. That will come at a high consumer cost as well as a large carbon footprint due to the energy intensity of the

treatment process.

Accordingly, copious articles address treatment R&D and cost studies in recent literature. Here’s a simple summary of just one cost study to show that

the costs are indeed significant.

http://www.epa.state.il.us/water/nutrient/presentations/nick_menninga_1.pdf

As the solid waste issue mounts, your product obviously seems like a smart alternative to anyone who doesn’t think in terms of mass balances or where “away” is. Perhaps one or two digesters in a sewershed are insignificant. However, it’s easy to imagine how if all the stores in one or more grocery chains or a number of other large scale food operations adopt this approach, that the nutrient problem will be multiplied.

Having worked as a regulator, I can also imagine how POTW pretreatment programs would work backwards in the sewershed to limit the discharge of individual businesses that discharge nutrients to their system.

Since your focus is on the solid waste side, these may be issues that you have not yet considered.